Available Student and Research Projects

(→M.Sc. projects for 2007/08) |

(→Micro-Manipulation) |

||

| Line 60: | Line 60: | ||

==Micro-Manipulation== | ==Micro-Manipulation== | ||

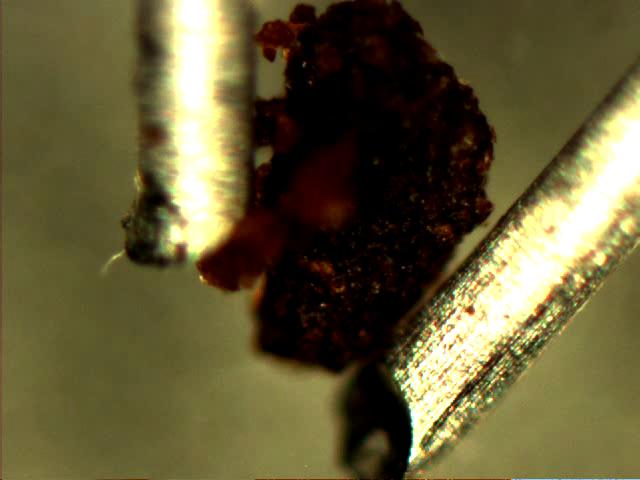

[[Image:Demarest_manipulation.jpg|thumb|right|180px|Micro manipulator picking up a crumb of ground coffee]] | [[Image:Demarest_manipulation.jpg|thumb|right|180px|Micro manipulator picking up a crumb of ground coffee]] | ||

| − | This project is about manipulating objects which can be seen under a microscope. The size of the objects typically is up to about 750 micrometers. | + | This project is about manipulating objects which can be seen under a microscope. The size of the objects typically is up to about 750 micrometers. An optical microscope with a motorized stage and a low-cost firewire video camera. There is an early prototype of a gripper mounted on a microtranslation stage. Parts with limited accuracy can be manufactured using [http://en.wikipedia.org/wiki/Rapid_prototyping rapid prototyping] or in the lab. |

| − | |||

| − | |||

| − | |||

| − | |||

The task is to construct and build a more advanced gripper. Possible ideas are: | The task is to construct and build a more advanced gripper. Possible ideas are: | ||

* Use [http://en.wikipedia.org/wiki/Strain_gauge strain gauges] to have feedback | * Use [http://en.wikipedia.org/wiki/Strain_gauge strain gauges] to have feedback | ||

* Develop gripper with more degrees of freedom | * Develop gripper with more degrees of freedom | ||

| − | ===See Also=== | + | ====See Also==== |

* [[Micromanipulators]] | * [[Micromanipulators]] | ||

| − | ===External Links=== | + | ====External Links==== |

* John Speich, Michael Goldfarb: [http://journals.cambridge.org/article_S0263574799001903 A compliant-mechanism-based three degree-of-freedom manipulator for small-scale manipulation] (PDF) | * John Speich, Michael Goldfarb: [http://journals.cambridge.org/article_S0263574799001903 A compliant-mechanism-based three degree-of-freedom manipulator for small-scale manipulation] (PDF) | ||

* Ying-Chien Tsai, Sio Hou Lei, Hendra Sudin: [http://www.iop.org/EJ/abstract/0960-1317/15/1/022 Design and analysis of planar compliant microgripper based on kinematic approach] | * Ying-Chien Tsai, Sio Hou Lei, Hendra Sudin: [http://www.iop.org/EJ/abstract/0960-1317/15/1/022 Design and analysis of planar compliant microgripper based on kinematic approach] | ||

Revision as of 11:04, 17 April 2008

Student Projects

These are the projects currently being offered by the MMVL. If you wish to be supervised then please contact the listed supervisors directly for an interview. Note that we support projects at the undergraduate, ERASMUS, M.Sc. and Ph.D. levels.

The projects fall into the following categories:

- Machine vision

- Robotics

- Medical applications

Project areas

Artificial Forces for multirobot formation

This work consists of the study of different types of forces for formation generation and maintaining in multirobot systems. Simulation study of different robot behaviours (robot aggregation, group migration and obstacle avoidance) for a team of robots in a 2D environment using NetLogo.

Supervisor: Lyuba Alboul, (Jacques Penders), Assistant: Joan Saes-pons

Explicit inter-robot communication using Khepera III robots

This work consists of developing an algorithm for explicit inter-robot communication using IR proximity sensors. Software to be used: Webots (3D robot simulation software). The simulation will be tested on real Khepera III (small-size robots).

Supervisor: Lyuba Alboul, George Chliveros, Alan Holloway, (Jacques Penders)

Formation control of Khepera III robots

The project consists of implementing formation control on a group of 3 Khepera robots. Inputs for the control are the US and IR sensors mounted on the khepera III robots, the control consists of a set of attraction and repulsion forces. Supervisor: Lyuba Alboul, George Chliveros, Alan Holloway, (Jacques Penders)

Wall following behaviours for mobile robots

Abstract: the project consists of implementing wall following behaviour on a Khepera III robot using US and/or IR sensors mounted on the robot. Additionally a map of the environment is produced or 2 other khepera follow the wall follower in a formation.

Supervisor: Lyuba Alboul, George Chliveros, Alan Holloway, Amir Naghsh, (Jacques Penders)

Design of a I2C sensor interface for Khepera robots using an embedded microcontroller

Abstract: The project consists of designing, building and testing a sensor interface to be mounted on a Khepera robot. The system will be based around an embedded microcontroller which will interface to the Khepera using the I2C interface.

Supervisors: Alan Holloway, Joan Saez-Pons, George Chliveros, (Jacques Penders)

Design of miniature multi channel frequency counter for remote QCM sensing applications

Abstract: The project will involve research into a suitable method of measuring the frequency of an array of frequency based sensors. It is anticipated that either an embedded microcontroller or FPGA will be used. A prototype design should be made and suitable validation of the system performed.

Supervisors: Alan Holloway, A Nabok, (Jacques Penders)

Design of a microcontroller based Electronic nose for use on Khepera robots

Abstract: The project is based around the design of both a hardware and software interface for a small array of sensors which can be mounted on a Khepera robot. The project will involve some embedded microcontroller programming, electronic circuit design and PCB design/fabrication

Supervisor: Alan Holloway

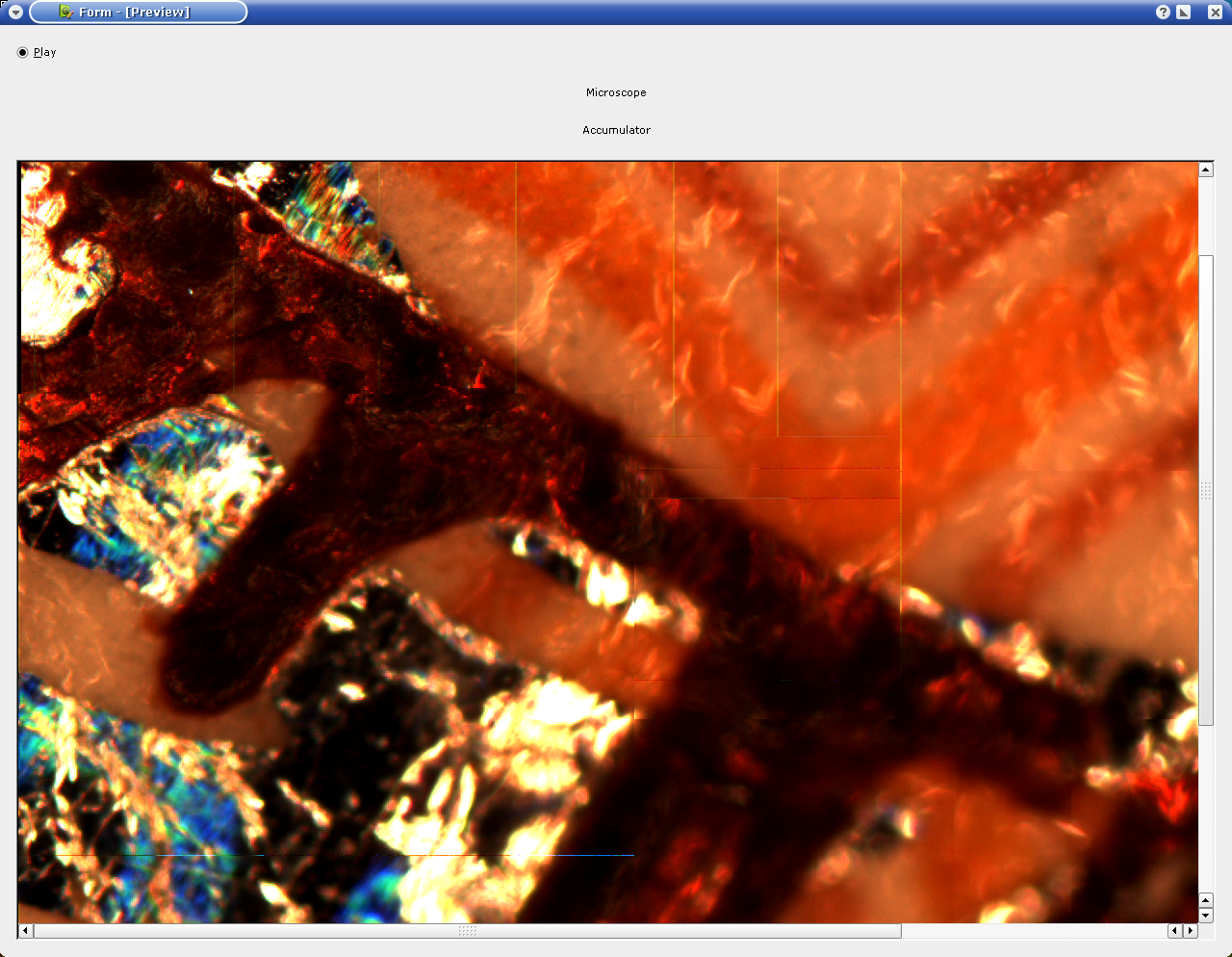

Stitching for microscopes

The objective ob this project is to generate a stitched image from the input-video (linear complexity desirable) without feedback from microscope-drive. The images need to be cross-compare to avoid drifts in the estimated shift. The system may be extended to include an extended depth of field by maximising a focus measure.

Supervisor: Jan Wedekind

See Also

External Links

Micro-Manipulation

This project is about manipulating objects which can be seen under a microscope. The size of the objects typically is up to about 750 micrometers. An optical microscope with a motorized stage and a low-cost firewire video camera. There is an early prototype of a gripper mounted on a microtranslation stage. Parts with limited accuracy can be manufactured using rapid prototyping or in the lab.

The task is to construct and build a more advanced gripper. Possible ideas are:

- Use strain gauges to have feedback

- Develop gripper with more degrees of freedom

See Also

External Links

- John Speich, Michael Goldfarb: A compliant-mechanism-based three degree-of-freedom manipulator for small-scale manipulation (PDF)

- Ying-Chien Tsai, Sio Hou Lei, Hendra Sudin: Design and analysis of planar compliant microgripper based on kinematic approach