MiCRoN

(Spiced up the page with images and videos.) |

m (Added introductory text about computer vision.) |

||

| Line 10: | Line 10: | ||

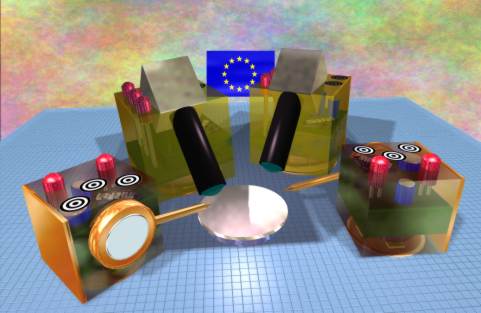

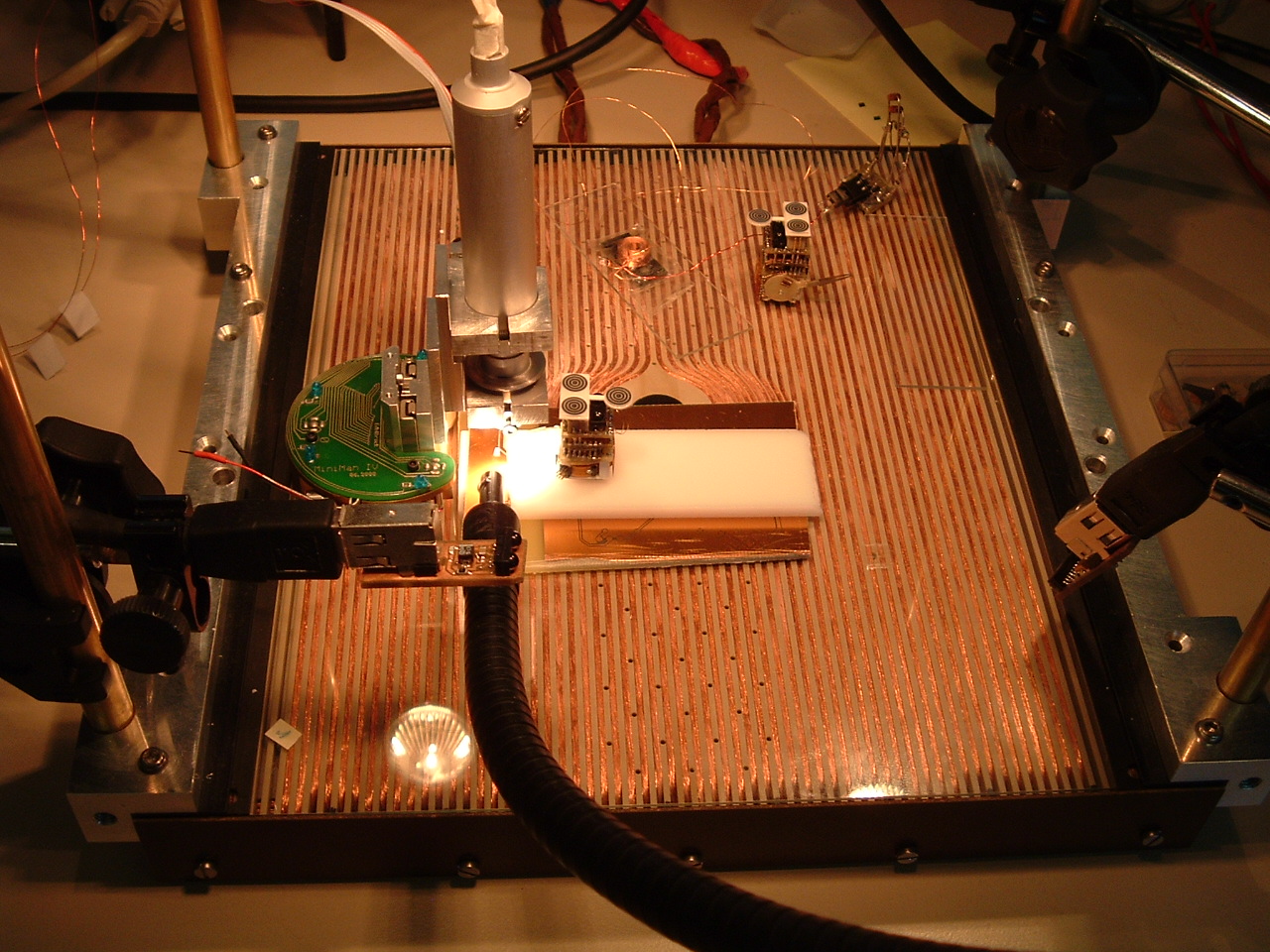

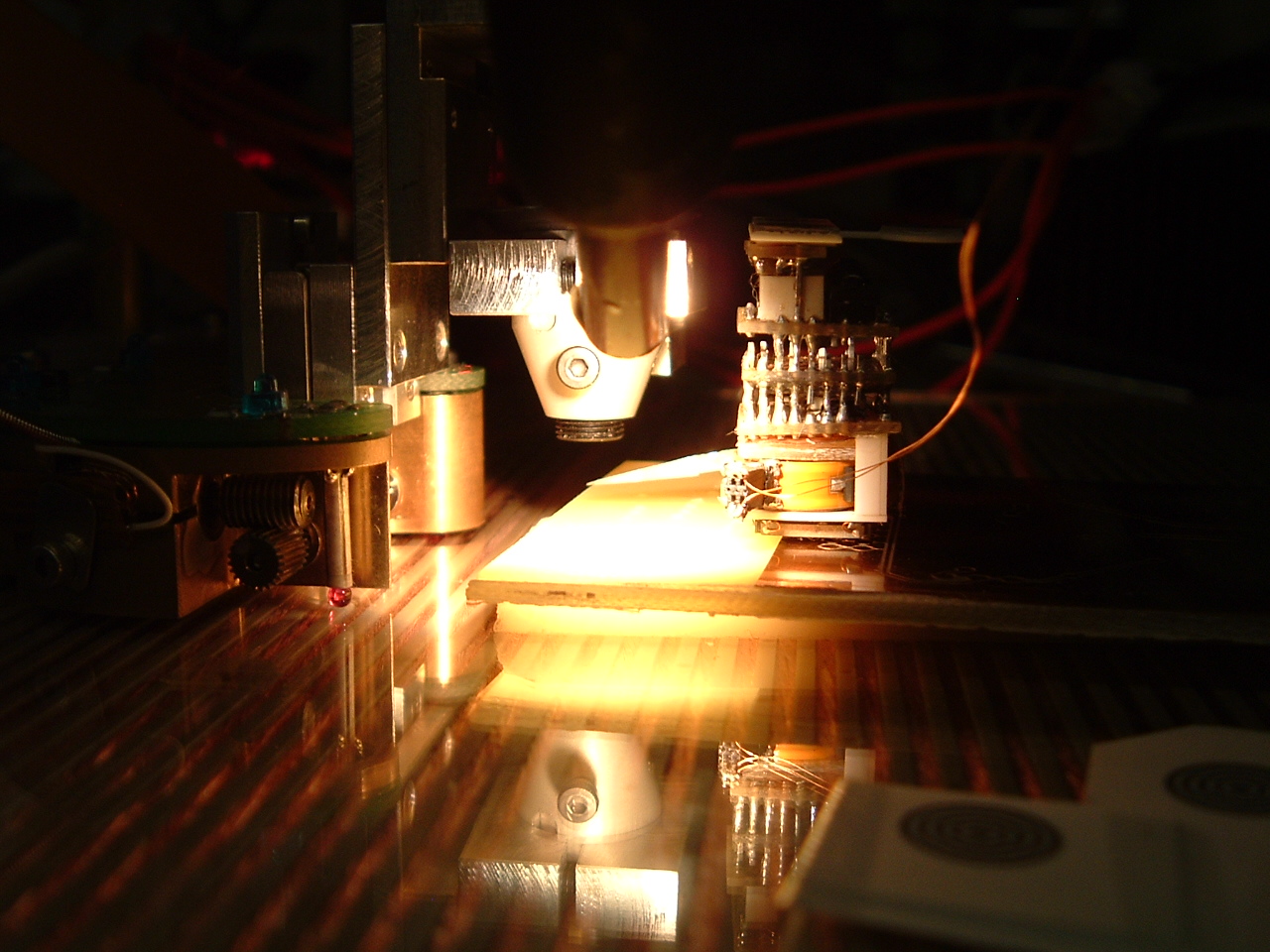

The goal of the European Union IST project '''MiCRoN''' was the development of a multi-robot manipulation system capable of handling µm-sized objects. The system is based on a small cluster of about a few cubic-centimetre-sized robots. Each robot is equipped with onboard electronics for communications and control. These robots are controlled by infrared communication and they can be equipped with various tools such as ''syringe-chips'', ''grippers'' or ''AFM probes''. The aim of the project was to automatically perform tasks like injecting cells with fluids or soldering SMD micro resistors. | The goal of the European Union IST project '''MiCRoN''' was the development of a multi-robot manipulation system capable of handling µm-sized objects. The system is based on a small cluster of about a few cubic-centimetre-sized robots. Each robot is equipped with onboard electronics for communications and control. These robots are controlled by infrared communication and they can be equipped with various tools such as ''syringe-chips'', ''grippers'' or ''AFM probes''. The aim of the project was to automatically perform tasks like injecting cells with fluids or soldering SMD micro resistors. | ||

| − | Members from Uppsala, Lausanne, St. Ingbert, Athens, Pisa, Barcelona, Karlsruhe and Sheffield have participated in this project. | + | Members from ''Uppsala'', ''Lausanne'', ''St. Ingbert'', ''Athens'', ''Pisa'', ''Barcelona'', ''Karlsruhe'' and ''Sheffield'' have participated in this project. The task of the [[MMVL]] was to develop computer vision software. |

| + | |||

| + | '''Computer vision for microscopes''' has to deal with the problem of limited depth of field. But instead of trying to | ||

| + | overcome this, one can actually use the depth information concealed in this images. | ||

| + | |||

| + | By using focus-stacks as models it was possible to provide real-time object recognition of multiple objects in up to 4 degrees-of-freedom. The micro-objects are not required to stay at a fixed distance to the camera any more. Novel automated procedures in biology and micro-technology are thus conceivable. | ||

=See Also= | =See Also= | ||

Revision as of 18:58, 16 December 2005

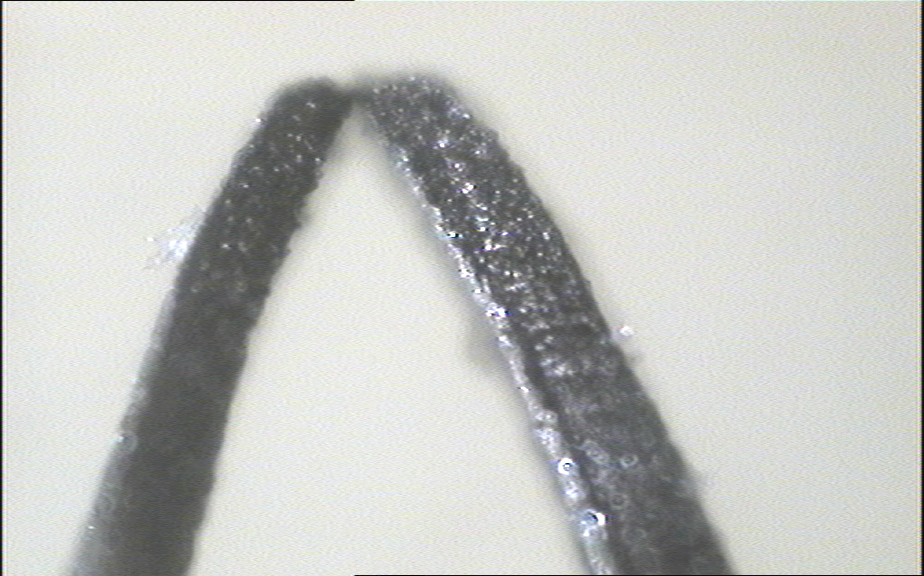

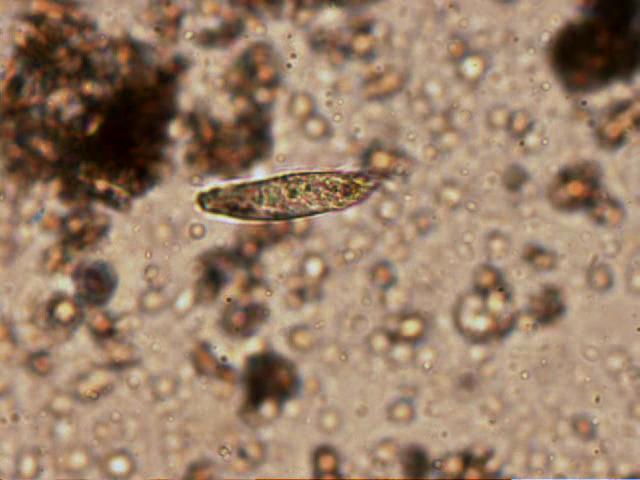

Microscope image with limited depth of field (934kByte video) |

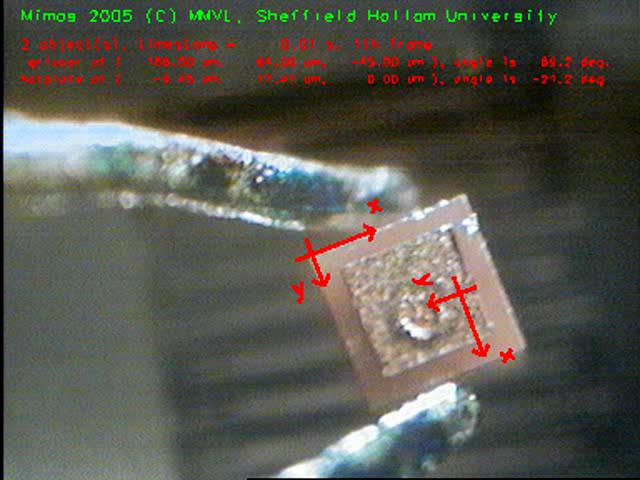

Detection/tracking of micro-gripper and capacitor (2.78 MByte video) |

The goal of the European Union IST project MiCRoN was the development of a multi-robot manipulation system capable of handling µm-sized objects. The system is based on a small cluster of about a few cubic-centimetre-sized robots. Each robot is equipped with onboard electronics for communications and control. These robots are controlled by infrared communication and they can be equipped with various tools such as syringe-chips, grippers or AFM probes. The aim of the project was to automatically perform tasks like injecting cells with fluids or soldering SMD micro resistors.

Members from Uppsala, Lausanne, St. Ingbert, Athens, Pisa, Barcelona, Karlsruhe and Sheffield have participated in this project. The task of the MMVL was to develop computer vision software.

Computer vision for microscopes has to deal with the problem of limited depth of field. But instead of trying to overcome this, one can actually use the depth information concealed in this images.

By using focus-stacks as models it was possible to provide real-time object recognition of multiple objects in up to 4 degrees-of-freedom. The micro-objects are not required to stay at a fixed distance to the camera any more. Novel automated procedures in biology and micro-technology are thus conceivable.