Microscope Environment

(Added image and video of bird's feather) |

(Added image of stitching) |

||

| Line 1: | Line 1: | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

=MiCRoN Tests With Microscope= | =MiCRoN Tests With Microscope= | ||

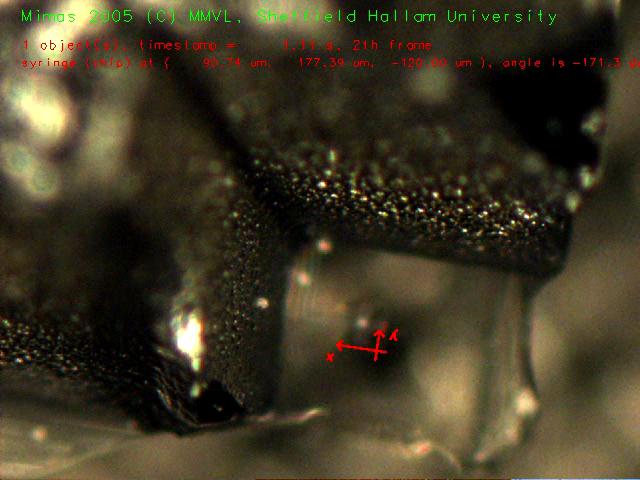

==Recognition/Tracking the Syringe Chip== | ==Recognition/Tracking the Syringe Chip== | ||

| Line 16: | Line 6: | ||

After the piece of sugar and the tungsten tip have been brought into field of view manually, the system automatically aligns the piece of sugar with the coordinate system of the camera. If you watch the video, you'll see, that every time the piece of sugar is lost by the vision system, the tungsten tip will be moved to a neutral position. | After the piece of sugar and the tungsten tip have been brought into field of view manually, the system automatically aligns the piece of sugar with the coordinate system of the camera. If you watch the video, you'll see, that every time the piece of sugar is lost by the vision system, the tungsten tip will be moved to a neutral position. | ||

| + | |||

| + | {|align=center | ||

| + | |- | ||

| + | |[[Image:Syringe3.jpg|thumb|250px|Object recognition and tracking of syringe chip in 3-D/4 DOF (16 MByte [http://vision.eng.shu.ac.uk/jan/syringe3.avi video])]]||[[Image:Solder.jpg|thumb|250px|Microscope image of small solder spheres]]|||[[Image:Sugarsetup.jpg|thumb|250px|Setup for automatically aligning a piece of sugar with the camera coordinate system (6.3 MByte [http://vision.eng.shu.ac.uk/jan/automated.avi video])]]||[[Image:Sugarpush.jpg|thumb|250px|Automated tungsten tip approaching the piece of sugar (6.7 MByte [http://vision.eng.shu.ac.uk/jan/sugarpush.avi video])]] | ||

| + | |- | ||

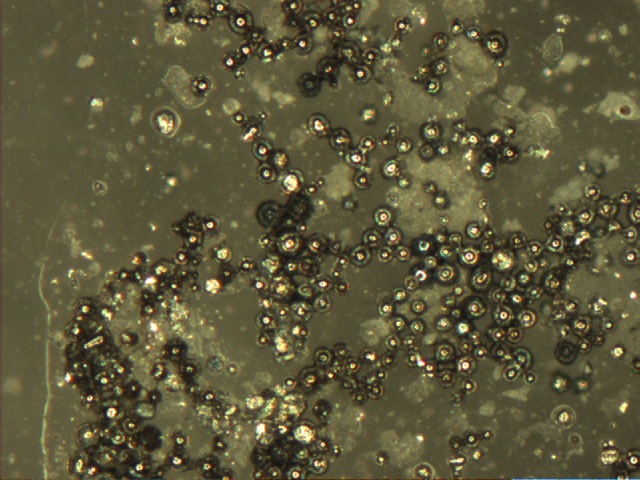

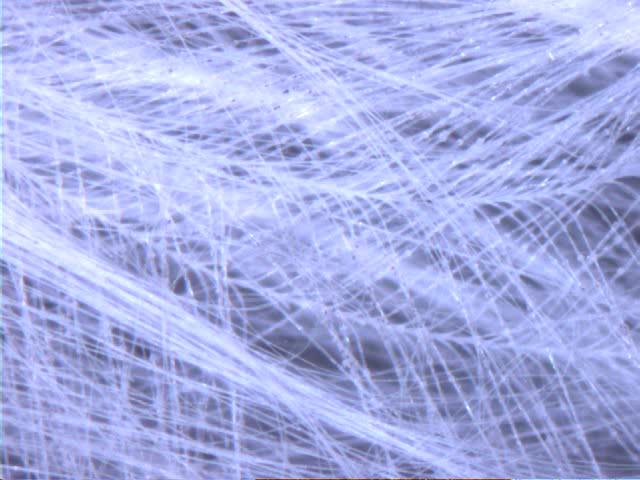

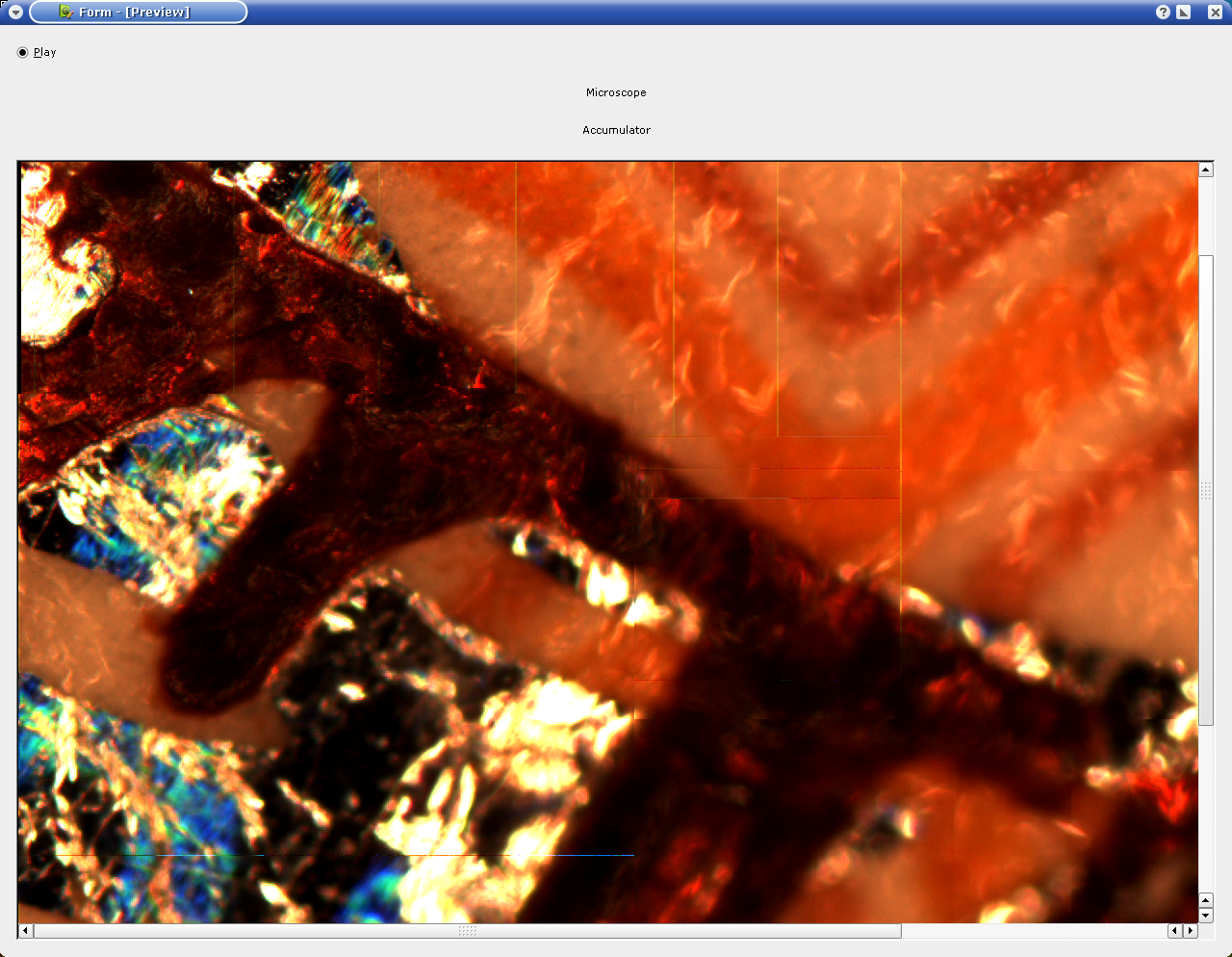

| + | |[[Image:Feather.jpg|thumb|250px|A bird's feather (reflected light, darkfield) (7.2 MByte [http://vision.eng.shu.ac.uk/jan/feather1.avi video], 10.1 MByte [http://vision.eng.shu.ac.uk/jan/feather2.avi video])]]||[[Image:Milk.jpg|250px|thumb|Microscope image of milk (9.5 MByte [http://vision.eng.shu.ac.uk/jan/milk.avi video])]]||[[Image:Mapping.png|250px|thumb|Stitching using the feedback of the microscope's drive]]|| | ||

| + | |- | ||

| + | |} | ||

=See Also= | =See Also= | ||

Revision as of 10:13, 28 September 2006

Contents |

MiCRoN Tests With Microscope

Recognition/Tracking the Syringe Chip

The same software, which was applied in the MiCRoN test environment also can be applied to a microscope. The video input in this case was a firewire digital camera (dc1394).

Rotating A Piece Of Sugar

If you have a motorized microscope, a fast camera and a computer, you just need vision software to do robotics under your microscope. Semi-automated tools, which are assisting the human operator, are conceivable. Here you can see a proof-of-concept for this.

After the piece of sugar and the tungsten tip have been brought into field of view manually, the system automatically aligns the piece of sugar with the coordinate system of the camera. If you watch the video, you'll see, that every time the piece of sugar is lost by the vision system, the tungsten tip will be moved to a neutral position.

Object recognition and tracking of syringe chip in 3-D/4 DOF (16 MByte video) |

Setup for automatically aligning a piece of sugar with the camera coordinate system (6.3 MByte video) |

Automated tungsten tip approaching the piece of sugar (6.7 MByte video) | |

Microscope image of milk (9.5 MByte video) |